Revolutionizing Sheep Counting: AI Technology at V&V Walsh

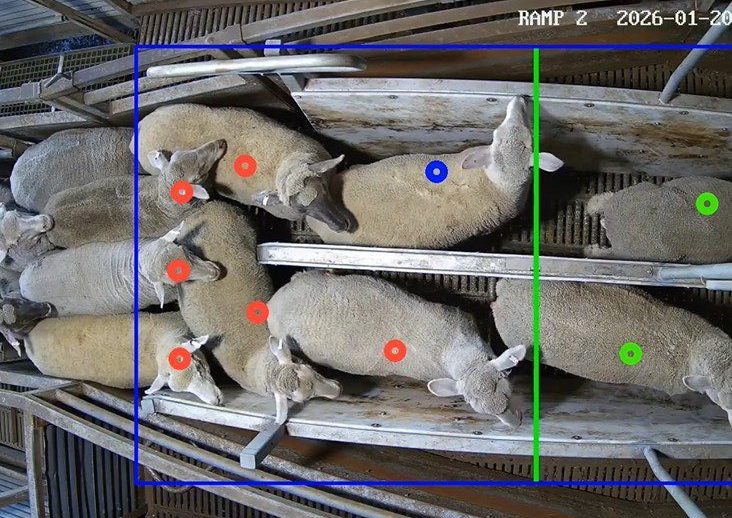

The system individually identifies and ‘tags’ each lamb and counts them as they pass a certain point in the race,

compensating for animals that turn back to avoid double counting. The orange dotted lambs in this image haven’t

been counted, the green dot lambs have been counted, and the blue dot lamb is a ‘turnback’ that has already

been counted.

Tallying sheep and lambs with cameras linked to a system featuring artificial intelligence (AI) has proven to be

faster and more accurate compared to traditional visual counting or electronic ear tag scanning. This innovation

is currently in use at the Bunbury processing facility of V&V Walsh, one of Western Australia’s major livestock

processors.

Discrepancies in sheep counts have historically led to significant frustrations among farmers, truck drivers, stock

agents, and meat processors. As lamb prices can exceed $300 per head, the financial impacts of miscounts can be

substantial, affecting both buyers and sellers.

A Better Counting Solution

At V&V Walsh, this problem is being tackled through an AI-powered counting system, installed in collaboration

with Brisbane-based AI Vision specialist, BlueSync. The system accurately identifies and records each animal as they

are unloaded from trucks, providing an instant tally at the end of the unloading process.

The AI technology not only counts the lambs as they pass a designated point but also tracks those that may

turn back, ensuring no animal is counted more than once. Once the count is completed, it is cross-verified against

the farmer’s count, as recorded on a waybill. If the numbers match, the consignment proceeds to the lairage;

discrepancies prompt a physical recount.

Boosting Efficiency and Trust

V&V Walsh General Manager Brent Dancer noted that accurately counting large numbers of sheep during fast

unloading was often challenging and artful. Count discrepancies could lead to disputes, making the transition to a scientific

approach essential.

“We conducted a comprehensive assurance process prior to deploying BlueSync’s AI counter, and it’s undeniable

that it is faster and more accurate,” Mr. Dancer stated. “In the event of a discrepancy, we have a video record for

each consignment, allowing us to audit the count at any time.”

This transparency instills confidence in both parties involved, reducing counting discrepancies that may strain

supplier-processor relationships. Mr. Dancer added, “It’s another illustration of how technology can address key

issues, allowing farmers to focus on raising their sheep while we efficiently process them for market.”

Scalability and Future Applications

V&V Walsh is capable of unloading up to 5,000 sheep and lambs per day, and the system is scalable, allowing for

the addition of more AI-linked cameras as required. Mr. Dancer cited instances where the AI count exceeded

the farmer’s count, ensuring fair pricing by paying the higher amount.

“Having an accurate counting system is crucial while transitioning through the challenges of RFID implementation,”

he explained.

The Technology Behind the System

According to BlueSync Technical Director Anthony Browne, the system does not employ facial recognition; instead,

it follows a frame-by-frame tracking method. Once identified, each sheep is tagged (marked with a dot) that follows

the animal throughout the counting process, accounting for any backward movements.

This tracking methodology guarantees that the AI model is reliable, distinguishing between sheep and other

objects, and is customizable for various livestock species. As Mr. Browne noted, “The model can be trained for any

species or object.” He emphasized the necessity of preparing the system for diverse sheep types and varying

lighting conditions, assuring accuracy amid challenges faced with RFID tag scanning.

Industry-Wide Impact

BlueSync’s technology is already being utilized in commercial applications at two sites: WAMMCO International

and V&V Walsh, both achieving accurate counts. Their systems provide complete data through integration with

abattoir livestock receival systems, enabling instant access to counts and video footage for auditing.

The technology is also adaptable for other types of livestock, including cattle, goats, and pigs. Trials at various

facilities have demonstrated its potential in addressing animal welfare issues and enhancing operational efficiency.

In conclusion, V&V Walsh’s adoption of AI-powered sheep counting marks a significant advancement in livestock

processing, promoting accuracy, reducing disputes, and enhancing trust between farmers and processors.

This HTML structure provides a well-organized article ready for integration into a WordPress platform, featuring appropriate headlines, paragraphs, and image captions for optimal readability.